Screw Conveyor Manufacturer in Ahmedabad, India

Vishvakarma Equipments are a leading Screw Conveyor Manufacturer in Ahmedabad, India. To meet the needs of industrial applications, we have been offering a wide variety of these Screw Conveyors of the highest quality and most durable.

We give companies the option to select our products for effective work by providing them with the newest and most cutting-edge tools or technology. To guarantee faultless operation and exceptional quality, our conveyors are designed and manufactured under the close supervision of quality controllers, skilled engineers, and other teams.

Along with being a Screw Conveyor Manufacturer In India Vishvakarma Equipments also produce Auger Feeder.

Auger Feeder vs. Screw Conveyor

Consider your precise needs for a minute before making a screw conveyor purchase. In reality, you could only require a typical transfer conveyor. Or perhaps an Auger feeder.

What precise distinctions exist between screw feeders and screw conveyors? The system's loading is where there is a crucial difference. There may be a clear winner for you, depending on the applications of your operation and the equipment you currently have.

Before buying any of these it is better to know the difference between these Auger Feeder and Screw Conveyor.

10 Advantages of Screw Conveyors

- Adaptability

- Efficient Mixer

- Bi-Directional Flight: Right and Left

- Easily Reversible

- Handles High Temperatures

- Moves Abrasive Materials

- Flood Loaded to regulate feed downstream

- Small to Large Lump Size

- Completely Enclosed

- Multiple Inlets or Discharges options

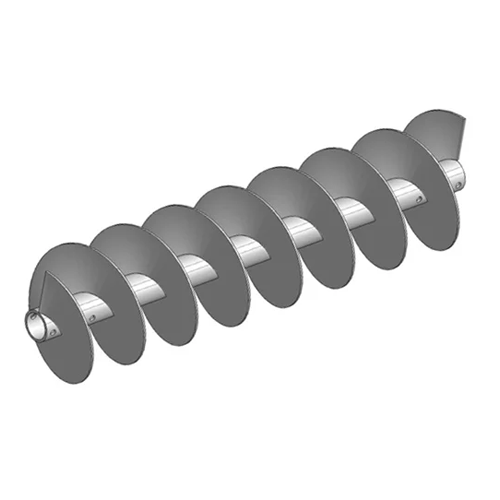

What Is a Screw Conveyor?

Material is transported over a flat or inclined plane using screw conveyors, which are also referred to as worm conveyors or spiral conveyors.

A screw conveyor transports the material in a predetermined quantity from an inlet point to an exit point. Based on the conveyor's size and horsepower, the material at the inlet is controlled.

On the basis of machine capacity and screw diameter, screw conveyors are assessed throughout time. Dissolving the lumps into the material they are working with is one of their most crucial duties.

These Conveyors transport a variety of products, including dry and wet items as well as small grains and boulders.

What is an Auger Feeder?

To regulate how much product flows through your system and is dispensed at any particular time, you employ an auger feeder. It is therefore perfect for measuring or packing products in precise amounts. The feeder, which regulates the flow, is often located at the bottom of a bin or hopper.

Unlike Screw Conveyor No material is moved far by the auger feeder. It only calculates the pace at which material will be fed into the next process. The system adapts the rate at which material enters the system based on your procedures.

Vishvakarma Equipments is both Auger Feeder and Screw Conveyor Manufacturer In India.

How Does a Screw Conveyor Operate?

Screw conveyors transport granular or liquid materials down a trough or tube using flighting, or rotating spiral blades.

The Archimedes screw, which has been used for moving water and other materials for more than 2500 years, serves as the foundation for this technique.

Screw conveyors are used in a variety of modern sectors, from agriculture to food processing.

Farmers use the modern screw conveyor with very few moving parts to transport grain to or from bins, grain baskets, or trucks, miners use screw conveyors to transport minerals from dig sites to storage silos for processing while chemical workers use screw conveyors to safely convey toxic substances from one application to another.

Important characteristics of our Screw Conveyor:

- Small size

- Dependable performance

- Dynamic performance

Applications of Screw Conveyors

The screw conveyors' efficient operating method and superior results make them useful in a variety of applications. Among them are:

In the bulk material handling sector, screw conveyors are most frequently used to move bulk items between locations at a steady and controlled rate.

The dust from production chains is collected using standard filters, jet pulse filters, or dust collectors in a number of manufacturing industries. Screw conveyors are crucial in this situation for clearing the collected dirt.

Screw conveyors are utilized in some of the larger industries for operations like feeding, mixing, batching, and grinding.

Agricultural equipment like threshers and balers use screw conveyors to transport materials.

If you are looking for a reliable Auger Feeder or Screw Conveyor Manufacturer In Ahmedabad you should contact Vishvakarma Equipments.